After 30 years of business activity in steel trade and steel processing sector, we continue to improve our services by incorporating advanced technology machinery, thus being able to offer services of high quality and superior accuracy.

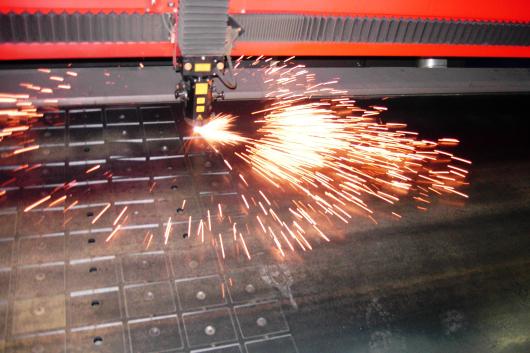

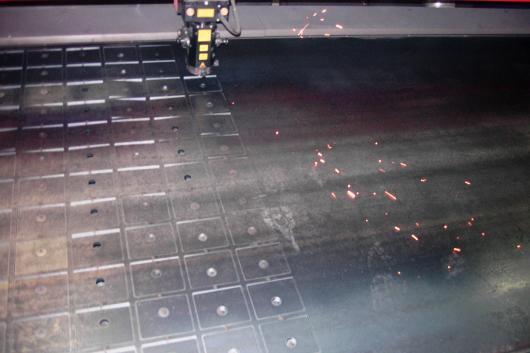

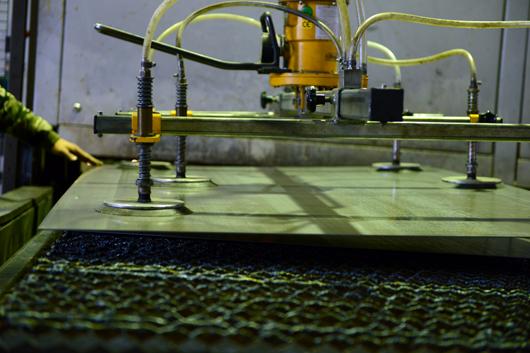

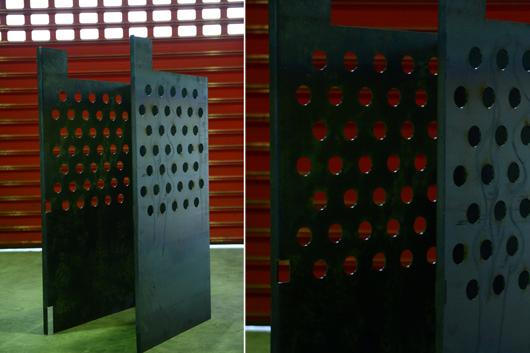

Our newest independent facilities host the state-of-the-art laser cutting machine Bystronic Bystar 3015, which offers unmatched quality, speed and versatility in cutting sheet metal and furthermore creating high fidelity metal components.

Our newest independent facilities host the state-of-the-art laser cutting machine Bystronic Bystar 3015, which offers unmatched quality, speed and versatility in cutting sheet metal and furthermore creating high fidelity metal components.

We also invested in human workforce by hiring highly-specialized stuff that is occupied in our new design studio or in managing our laser-cutting machinery.

Advantages gained from using laser cutting

- High quality of cutting surface and produced parts

- No need for whetting or finishing procedures

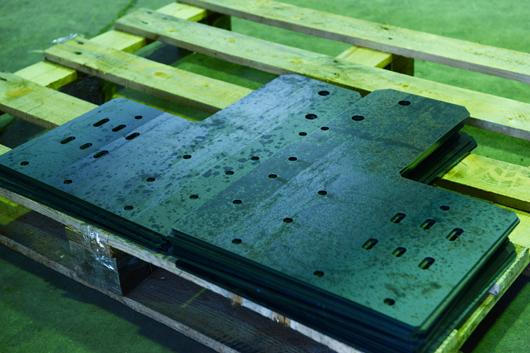

- Maximum use of raw materials (Nesting)

- Contact-less cutting procedure with minimum to none heated zone (ΗΑΖ) and oxide free, factors that lead to trouble-free welding

- Absolutely vertical cutting surface

- Identical repeated cutting of parts

- Great versatility in design changes

- Quick prototypes retrieval for repeated orders

- Ability to process all types of sheet metal

- Time saving process

- Ability to offer optimized construction solutions based on improved design

- Special types of welding

- Clasps. Quick and easy assemblage

- Ability to produce a huge range of different products (from a plain grommet to high accuracy machine parts and accessories)

- Purchase and management of certified raw materials