Electrostatic painting is a manufacturing process that employs charged particles to more efficiently paint a metal workpiece with special epoxide, epoxide-polyester or polyester resins, resulting in improved corrosion protection and high quality colorization and finish.

For metal parts intended for use in architectural applications (doors, windows, curtain walling etc), we use polyester powders. This category of polyester powders are characterized by long endurance in outdoor conditions.

For metal parts intended for use in architectural applications (doors, windows, curtain walling etc), we use polyester powders. This category of polyester powders are characterized by long endurance in outdoor conditions.

Electrostatic metal painting consists of the below stages:

Surface cleaning: Before main paint procedure, metal parts get cleaned by using chemical means, thus removing foreign particles, like dust or fats.

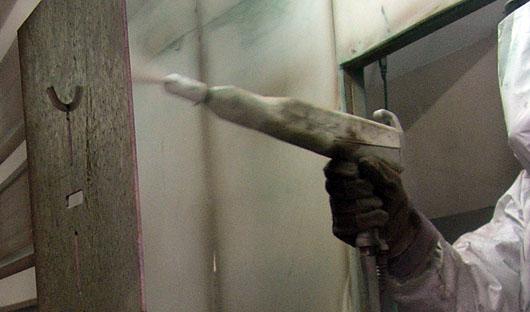

Paint: The primary stage of the process is the application of the electrostatically charged powder to the metal surfaces. The paint powder is charged at a level around 70-100 ΚV and then thrown through pressurized air onto the metal parts, that are grounded. The electrostatic voltage difference´s main effect is the depositing of paint particles on the metal surface. Final adhesion of paint is achieved at the next stage, the polymerization of paint particles at the ovens.

Polymerization: After proper paint application, metal parts are guided to special ovens, that reach temperatures between 180 and 220°C for a time period dictated by the powder manufacturer. In this process, resins become polymerized and form the stable and durable paint layer, resulting in superior metal coating.

Quality characteristics of electrostatic metal painting

Final product paint quality is affected by many factors and requires a series of checks and tests. The key factors that affect final quality are:

Special installations: Electrostatic coating requires special installations, use of sophisticated equipment and strict control of production conditions.

Appearance: Surfaces should free from deep scratches that get inside metal or other anomalies like: streaks, encapsulated foreign particles, craters etc. Layer of paint should display color uniformity and proper covering when observed from a minimum of 5 meter distance for outdoor parts surfaces or from a minimum of 3 meter distance for indoor parts surfaces.

Color: Almost unlimited variety of colors that can be achieved with electrostatic painting is one of the factors that impacted it´s large adoption. This variety sometimes creates problems in communication between the paint workshop and the final customer. Colors are encoded using the RAL system. Main colors have a different RAL code. (ex. among codes there is a white RAL 9010 and a white RAL 9016).

Mechanical strength: Mechanical strength encapsulates grip properties, hardness (scratch resistance) and elasticity (bend and percussion resistance) of the coating.